| |

|

|

| |

|

PRODUCTS |

|

|

| |

|

|

| |

TIMER PANELS |

|

| |

|

|

| |

On Line & Off Line Control Panels

When it comes to large Bag Houses for Bag cleaning operation

there are two type of such systems

|

|

| |

|

SINGLE

LARGE MODULAR BAG HOUSE |

| • |

ON LINE CLEANING |

|

NO.

OF BAG HOUSES IN PARALLEL |

| • |

OFF LINE CLEANING

|

| • |

REVERSE AIR BAG HOUSE

(RABH) CLEANING |

|

|

| |

|

|

| |

|

OPERATION

OF SINGLE LARGE MODULAR BAG HOUSE : |

|

Normally the bag house bag cleaning

operation is done by using reverse jet high-pressure

air Pulsing Via Diaphragm type pulse valve. For

this purpose a solid-state sequence controller

is normally employed .A single controller of this

type usually suffices for solenoid rows up to

40 numbers. Big Bag filters (more than 40 rows)

are not easy to clean with single sequential controller

so that Bag house delta “P” is maintained

for efficient cleaning & to meet the emission

norms.

For large no of solenoid rows following procedure

is normally adhere to (on line modular cleaning).

No of sequence controller are grouped to perform

such cleaning operation at a time. Such a On Line

Cleaning for Big Bag house cleaning system is,

called as module pulsing. (Implemented using grouping

of bag rows & respective air headers).

For such case Module programming is executed

in pairs of sequence controller simultaneously

, firing air header solenoids. Like wise all total

solenoids would be driven by respective allocated

module controllers.

The supervisory controller for this purpose is

called as Master controller.

• Which keeps the module sequence in line

as per program. (Programmed in such a way that

it sends signals to each module pair.)

• Generates On Time & Off Time (Interval

times) Common clock pulse for all the modules

• Checks Delta “P” continuously

during Module sequencing & pulsing operation

If in case delta “P ”is high then substitutes

interval time to crash mode interval time (normally

50% of interval time). This is crash mode system.

|

| |

|

|

OPERATION

OF NUMBER. OF BAG HOUSES IN PARALLEL : |

| • |

OFF

LINE CLEANING |

|

In this system no of dust collector

modules (actually Bag houses) (see 3d

drawing) maximum up to 8 numbers are allowed

to collect dust By on line method. The cleaning

of bags is done by closing inlet damper so that

the said bag house unit stops collecting the dust

& gets isolated from from others. When in

isolation (off the line) its bags are cleaned

by reverse air pulse jet of individual sequence

timers. This is accomplished by master sequence

controller. This sequence timer is also termed

as Compartment sequence controller.

|

| • |

REVERSE AIR BAG HOUSE

(RABH) |

|

In reverse-air bag houses, the

bags are fastened onto a cell plate at the bottom

of the bag house and suspended from an adjustable

hanger frame at the top. Dirty gas flow normally

enters the bag house and passes through the bag

from the inside, and the dust collects on the

inside of the bags.

Reverse-air bag houses are compartmentalized

to allow continuous operation. Before a cleaning

cycle begins, filtration is stopped in the compartment

to be cleaned. Bags are cleaned by injecting clean

air into the dust collector in a reverse direction,

which pressurizes the compartment. The pressure

makes the bags collapse partially, causing the

dust cake to crack and fall into the hopper below.

At the end of the cleaning cycle, reverse airflow

is discontinued, and the compartment is returned

to the main stream.

|

|

|

| |

|

|

| |

Key Features : |

|

| |

|

High technology |

|

Rittal (Germany) Enclosures

|

|

High quality product

|

|

Custom designed for

ecologically reactive and superb bag house control

|

|

Affordable Prices

|

|

|

| |

|

|

| |

|

|

|

|

|

Bag House System Timer Panels

|

Double Door Timer

|

Timers Cascaded

|

| |

|

|

|

|

|

|

|

With DWYER Photohelic Gauge

.....

|

Timer in NEMA

Box Open View |

|

|

|

| |

|

|

| |

On Demand Pulsing Timer mode (means

Pulsing when just required) :

An improved Bag Cleaning control can be achieved with

a high and low limit relay contact set which are provided

in the Photohelic® (DWYER Make) indicating set points

pressure gage. In this on demand mode, on time and off

time may be programmed to define the cleaning cycle.

Meaning there by Pulsing will start when DP (Delta "P")

is high & continue till it reaches low set point.

...

|

|

| |

|

|

| |

BAG HOUSE SYSTEM PANELS

IN RITTAL ENCLOSURES |

|

| |

|

|

| |

|

|

|

|

|

|

|

|

Bag House Panel Diagram

of panel

Rittal Enclosure |

On Line Bag House Panel 220

solenoids Electrical Diagram

of panel |

Offline

Cleaning Panel with 6 Compartment modules

|

|

|

| |

|

|

| |

|

|

| |

|

|

|

|

| |

|

|

|

|

|

|

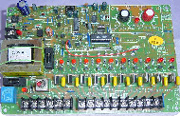

10Way CSC (slave) board

|

15Way (CSC) slave board

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

|

|

|

Master Controller board

|

Programming & Display Unit

|

|

|

|

| |

|

|

| |

*RABH Reverse Air Bag

House |

|

| |

|

|

| |

Click to See here Terms

& Conditions of sale , International sale Terms

& Conditions of sale |

|

| |

|

|